Analyze the government’s efforts to support the expansion of small and medium-sized businesses (SMEs) in the manufacturing sector, including the steps taken to increase market, credit, and technological accessibility. Assess the effects of these initiatives on the creation of jobs, ...

Home/upsc: manufacturing sector/Page 2

- Recent Questions

- Most Answered

- Answers

- No Answers

- Most Visited

- Most Voted

- Random

- Bump Question

- New Questions

- Sticky Questions

- Polls

- Followed Questions

- Favorite Questions

- Recent Questions With Time

- Most Answered With Time

- Answers With Time

- No Answers With Time

- Most Visited With Time

- Most Voted With Time

- Random With Time

- Bump Question With Time

- New Questions With Time

- Sticky Questions With Time

- Polls With Time

- Followed Questions With Time

- Favorite Questions With Time

Mains Answer Writing Latest Questions

Ritu tyagiLearner

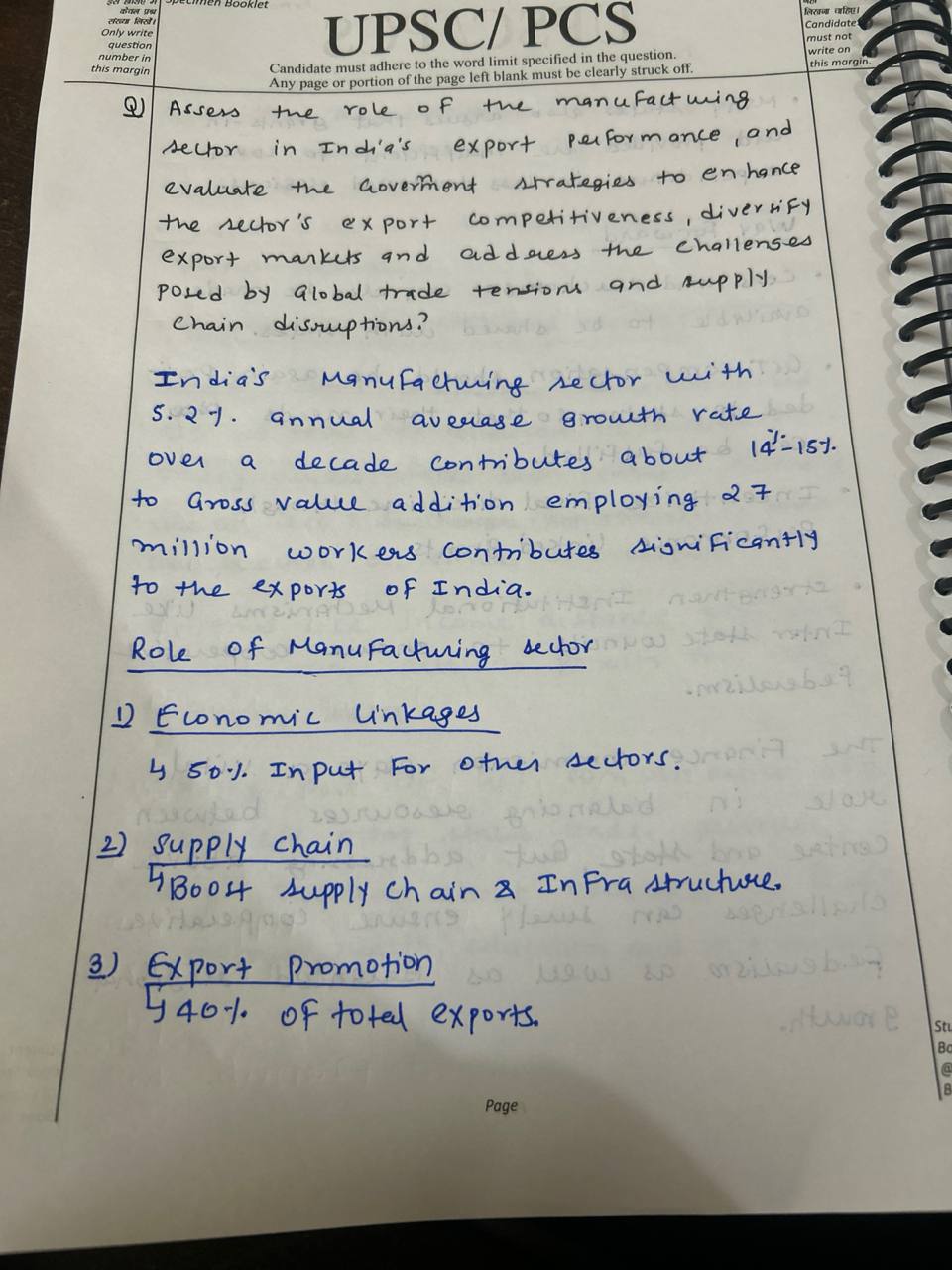

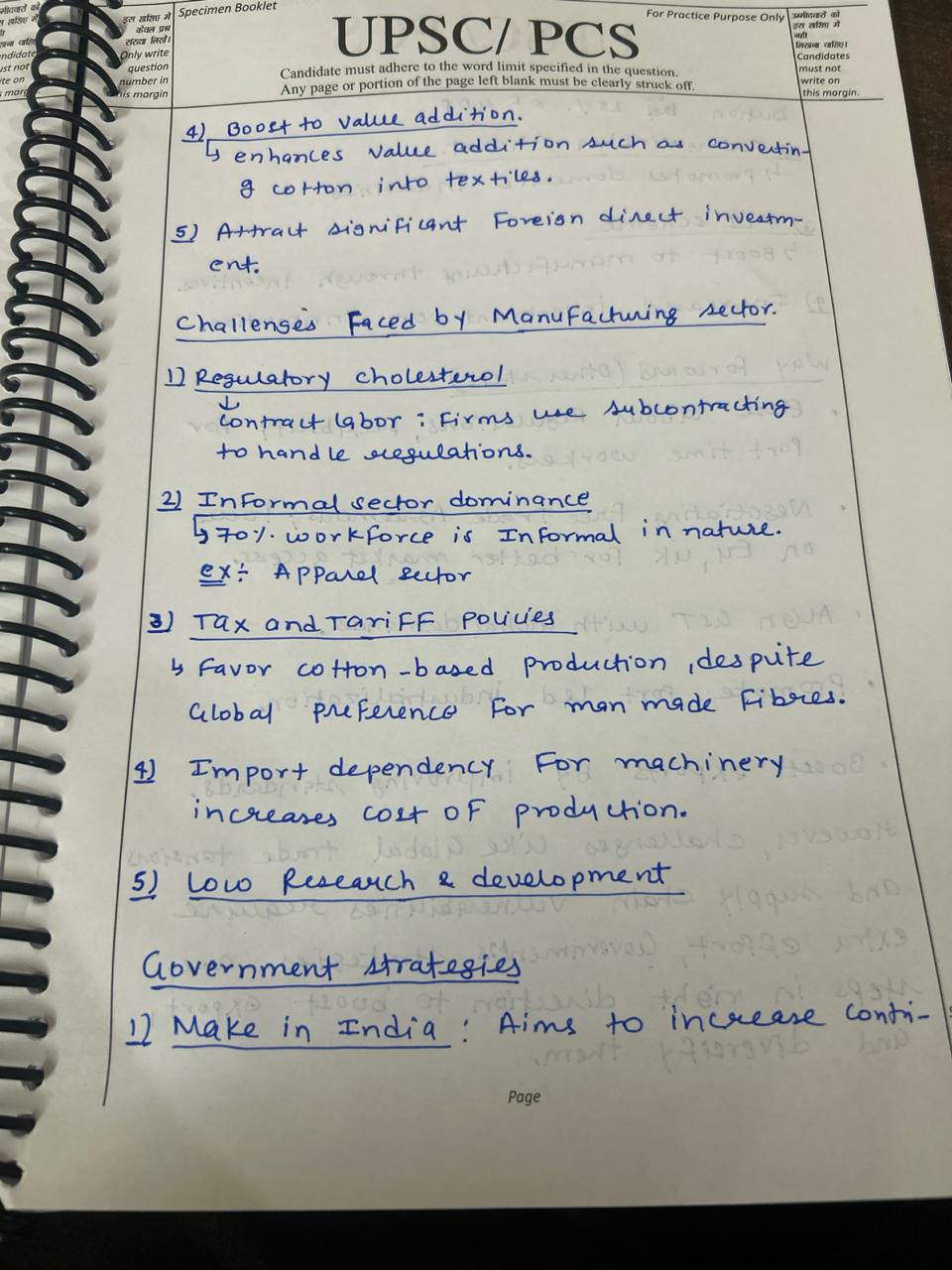

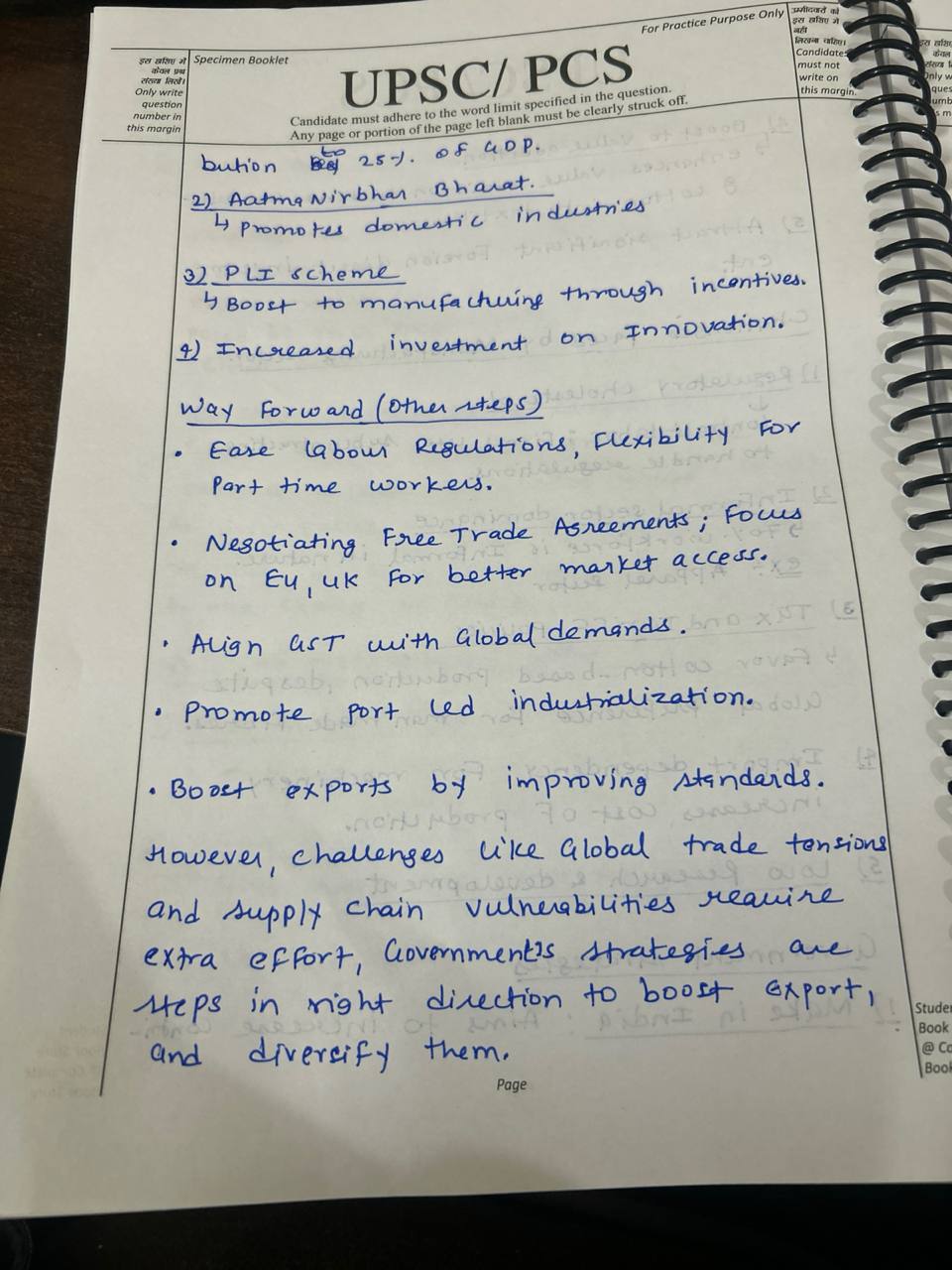

Analyze how the manufacturing sector contributes to India’s export performance and the government’s efforts to diversify export markets, increase the sector’s export competitiveness, and deal with supply chain disruptions and conflicts in the global trade arena.

Government Initiatives to Promote the Growth of Small and Medium Enterprises (SMEs) in the Manufacturing Sector Introduction Small and Medium Enterprises (SMEs) are vital to India’s manufacturing sector, contributing significantly to employment, innovation, and industrial growth. The Indian governmeRead more

Government Initiatives to Promote the Growth of Small and Medium Enterprises (SMEs) in the Manufacturing Sector

Introduction

Small and Medium Enterprises (SMEs) are vital to India’s manufacturing sector, contributing significantly to employment, innovation, and industrial growth. The Indian government has implemented various initiatives to support SMEs, focusing on improving access to credit, technology, and markets. This discussion examines these initiatives and evaluates their impact on employment generation, innovation, and the overall industrial ecosystem.

Government Initiatives for SMEs

Improving Access to Credit

Pradhan Mantri Mudra Yojana (PMMY): This scheme provides collateral-free loans up to ₹10 lakh to SMEs, aiming to improve access to credit. Under PMMY, MUDRA banks offer financial assistance to small businesses, enabling them to expand operations and invest in technology. For example, small textile units have benefited from this scheme to enhance their production capabilities.

Credit Guarantee Fund Trust for Micro and Small Enterprises (CGTMSE): This trust provides credit guarantees to banks and financial institutions, encouraging them to lend to SMEs. The scheme has facilitated easier access to credit for many small businesses. For instance, auto-component manufacturers have accessed loans under CGTMSE to upgrade machinery and increase production.

Stand-Up India Scheme: Targeting SC/ST and women entrepreneurs, this scheme provides loans between ₹10 lakh and ₹1 crore for setting up greenfield enterprises. The scheme has enabled many new manufacturing ventures to start and grow, such as women-led manufacturing units in the food processing sector.

Enhancing Access to Technology

Technology Upgradation Fund Scheme (TUFS): TUFS provides financial assistance to SMEs for upgrading technology and improving efficiency. The scheme has been instrumental in modernizing industries like textiles and leather, where technological improvements have led to increased productivity and product quality.

National Manufacturing Competitiveness Programme (NMCP): This program offers support for technology adoption and process improvements in SMEs. For instance, metal fabrication units have used NMCP funds to acquire advanced machinery, leading to enhanced production capabilities and competitiveness.

Digital MSME Scheme: This scheme promotes digitalization among SMEs by providing financial support for adopting IT tools and software. Companies like small electronics manufacturers have leveraged this initiative to improve their business processes and online presence.

Facilitating Market Access

National Small Industries Corporation (NSIC): NSIC helps SMEs access domestic and international markets through various programs, including marketing assistance and participation in trade fairs. The Export Promotion Scheme under NSIC has enabled many SMEs to explore new international markets for their products.

eMarketplace Initiatives: The Government e-Marketplace (GeM) platform allows SMEs to participate in government procurement processes. This initiative has provided a significant market opportunity for SMEs, such as local manufacturers of office supplies who now have easier access to government contracts.

Startup India Scheme: This scheme includes provisions for market access and business support for startups, many of which are SMEs in the manufacturing sector. The Startup India Hub connects startups with mentors, investors, and market opportunities, fostering growth and market entry.

Impact on Employment Generation, Innovation, and the Industrial Ecosystem

Employment Generation

Job Creation: Initiatives like PMMY and CGTMSE have led to the creation of numerous jobs in the manufacturing sector. For example, small-scale manufacturing units in sectors like textiles and consumer goods have expanded their workforce, contributing to job creation in local communities.

Skill Development: Programs such as the Skill Development Mission associated with these initiatives have enhanced the employability of individuals, ensuring that SMEs have access to a skilled workforce. This has resulted in better productivity and efficiency in manufacturing operations.

Innovation

Technological Advancements: Access to credit and technology has enabled SMEs to invest in research and development (R&D) and innovative processes. For instance, startups in the electronics sector have developed cutting-edge products due to the support from initiatives like the Digital MSME Scheme.

Process Improvement: The adoption of new technologies and practices facilitated by programs like TUFS has led to significant process improvements and innovations in manufacturing. Textile manufacturers have implemented advanced dyeing technologies, resulting in more sustainable and efficient production processes.

Overall Industrial Ecosystem

Strengthening the Ecosystem: Government initiatives have strengthened the industrial ecosystem by integrating SMEs into larger supply chains and enhancing their capabilities. Automobile component suppliers have benefited from various support programs, becoming key players in the automotive sector’s value chain.

Boosting Competitiveness: The support for technology adoption and market access has improved the overall competitiveness of Indian SMEs. As a result, Indian manufacturing has become more robust and capable of competing globally. Pharmaceutical SMEs have expanded their market reach and improved their global presence due to enhanced competitiveness.

Conclusion

The government’s initiatives to support SMEs in the manufacturing sector have had a significant impact on improving access to credit, technology, and markets. These measures have contributed to employment generation, innovation, and the overall strengthening of the industrial ecosystem. Continued focus on addressing the evolving needs of SMEs and supporting their growth will be crucial for sustaining their contributions to India’s manufacturing sector and overall economic development.

See less